Products by Brand

Air Compressors

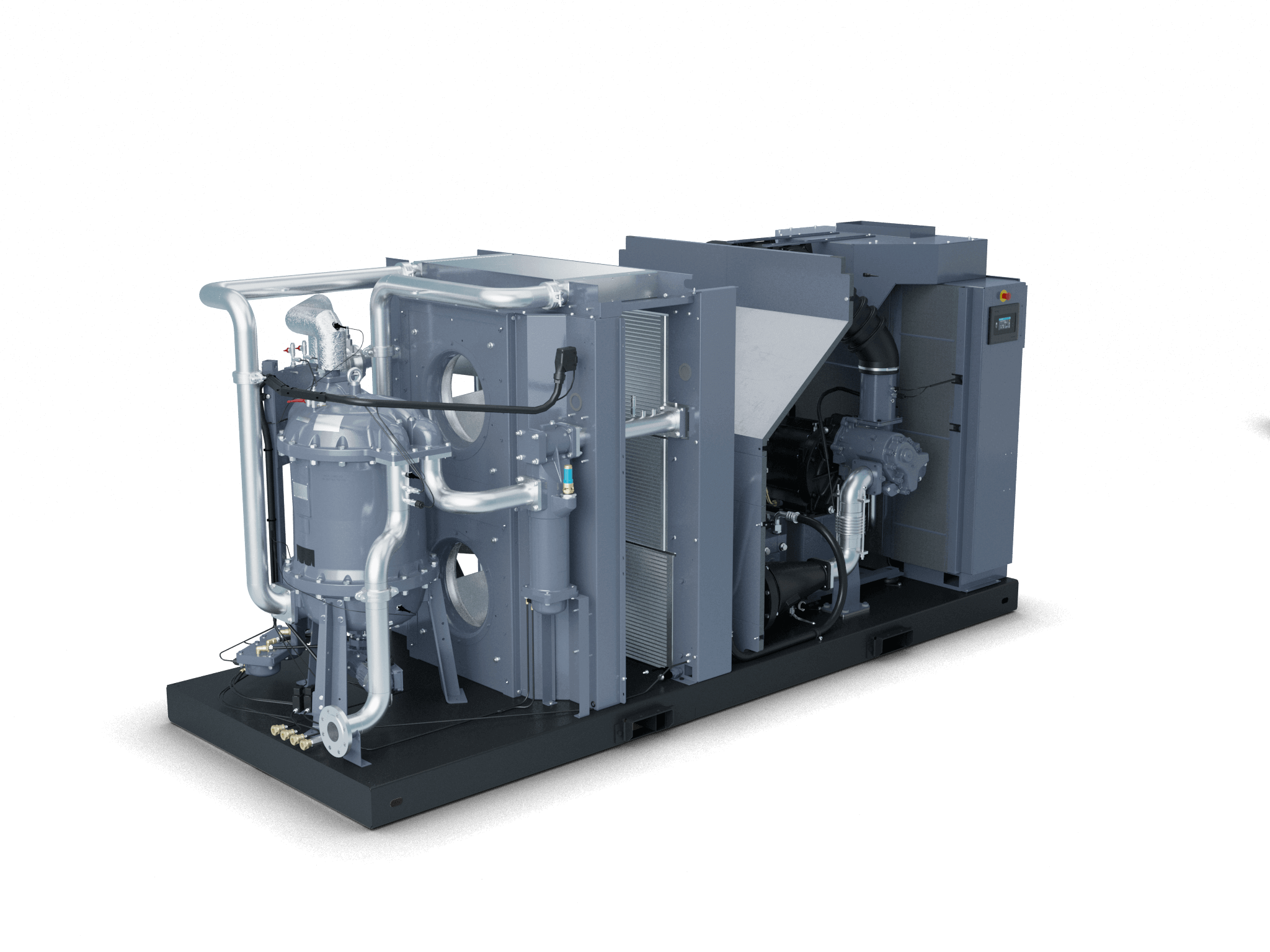

Oil-Free Air Compressors

The oil-free air compressor designed to deliver 100% clean, oil-free air, making it ideal for industries requiring the highest air purity standards. Atlas Copco offers oil-free product range that can be used in many processes such as Oil & Gas, Waste Water Treatment, Electricity, Cement, Pharmaceuticals, Food & Beverage.

Oil-Free Air Compressors Continer

An Oil-Free Air Compressor Container is a self-contained, ready-to-operate compressed air solution housed inside an ISO container. It delivers 100% oil-free compressed air while integrating the compressor, air treatment, control system, and auxiliaries in a compact, weather-proof enclosure

Oil-Injected Air Compressors

Offers reliable and efficient performance, suitable for a wide range of industrial applications requiring consistent compressed air supply.

Piston Air Compressors

Typical Use: - Workshops & Garages: Tire inflation, pneumatic tools, painting, cleaning - Small & Medium Industries: Packaging, woodworking, metal fabrication - Construction Sites: Portable air for drills, breakers, and tools - Service & Maintenance: Backup air supply, utility air - Remote / On-site Applications: Where simplicity and robustness are required

Electrical Portable Air Compressors

Electrical air compressors with zero fuel consumption, environment friendly, low maintenance cost.

Diesel Portal Air Compressors

Fuel driven air compressors that can operate in remote areas with no infrastructure or power supply availability.

Air Treatment

Desiccant Air Dryers

The Desiccant air dryer ensures extremely low dew points, providing dry air essential for sensitive processes and preventing corrosion in your compressed air systems.

Refrigerated Air Dryers

The refrigerated air dryers remove moisture from compressed air with a stable dew point, ensuring reliable protection against corrosion and moisture-related issues.

Compressed Air Filters

DD, PD, UD, QD, QDT filters

Filters effectively removes solid particles, water aerosols, and oil aerosols from compressed air, safeguarding your equipment and end products from contamination. Atlas Copco offers a range of DD, PD, UD, QD, QDT filters a. DD+ Filter – General Purpose Coalescing Filter Purpose: Removes bulk water, oil aerosols, and wet dust from compressed air. b. PD+ Filter – High-Efficiency Coalescing Filter Purpose: Eliminates fine oil aerosols and submicron particles. c. UD+ Filter – Combined Coalescing Filter Purpose: Integrates DD+ and PD+ filtration stages into a single unit. d. QD+ Filter – Oil Vapor Removal Filter Purpose: Adsorbs oil vapors and odors from compressed air. e. QDT Filter – High-Efficiency Oil Vapor Removal Purpose: Provides superior removal of oil vapors and hydrocarbons.

Gas Generators

Nitrogen Generators

The NG series utilizes Pressure Swing Adsorption (PSA) technology to produce high-purity nitrogen on-site, offering a cost-effective and reliable alternative to bottled or bulk nitrogen supply.

Oxygen Generators

The OGP5 oxygen generator employs PSA technology to deliver a continuous supply of oxygen with high purities, suitable for various applications including healthcare and metal processing.

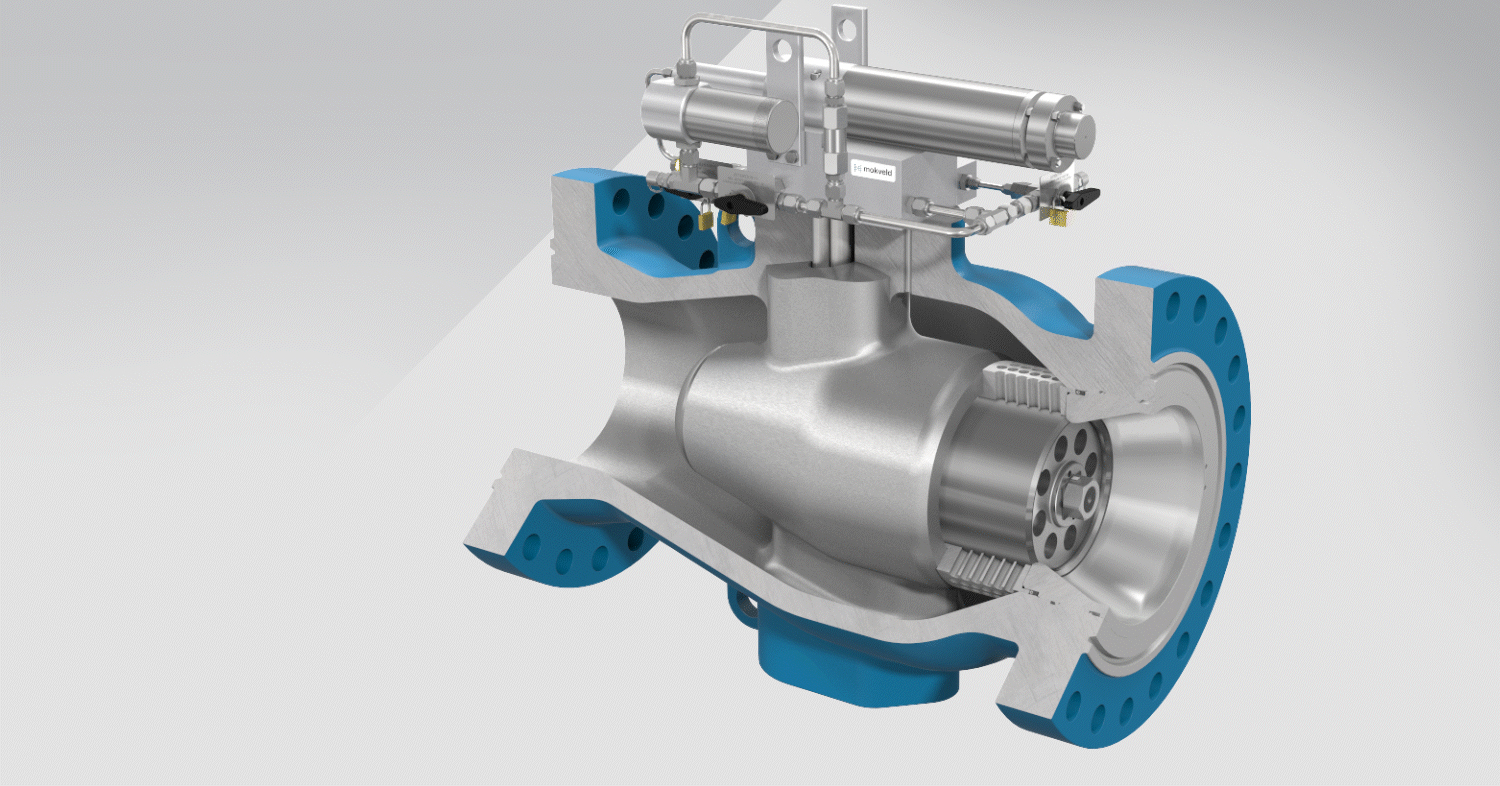

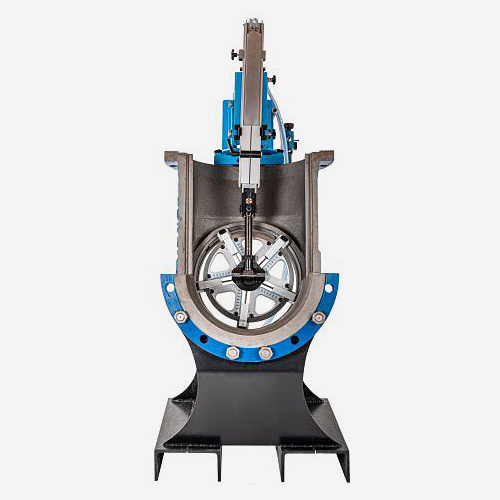

Axial on-off valve

This valve is specifically suitable for severe duty on-off (upstream) and for quick-acting safety applications (HIPPS, ESD). Pressure has no impact on the operating forces, and the valve can be opened against full differential pressure

Axial check valve

An axial check valve is the preferred solution for critical non-return applications such as the protection of rotating equipment and systems where low pressure loss, stable operation and dynamic behaviour are essential

Axial surge relief valve

The high-capacity proportional pilot design allows fast response and will eliminate the dangers of a pressure surge. All components operate solely on fluid static pressure to provide ultimate protection

Axial control valve

Selecting Mokveld axial control valves with proven reliable performance will help to reduce costly maintenance and lost production time; a choice that will ensure the safe and reliable operation of your plant

ABB LV & MV Motors

ABB Low Voltage (LV) and Medium Voltage (MV) motors are designed for high efficiency, reliability, and long service life across demanding industrial applications. They deliver consistent performance in continuous operation while reducing energy consumption and maintenance requirements

ABB Variable Frequency Drives (VFDs)

ABB VFDs provide precise motor speed and torque control, improving energy efficiency, process control, and equipment protection. They help extend motor life, reduce operating costs, and optimize system performance

Standards & Certification

All ABB motors and drives are manufactured in accordance with IEC standards and are supplied with full IEC certification, ensuring compliance with international electrical, safety, and performance requirements

LarsLap Model G

A large range, portable machine ideal for gate, parallel slide, globe, check, safety and control valves, discs and wedges.

LarsLap Model FL

A midrange portable machine for gate, parallel slide, globe, check, safety and control valves, discs and wedges.

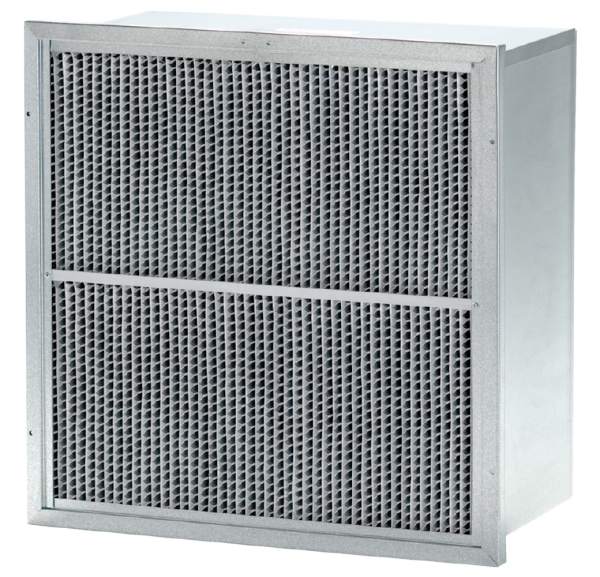

AstroCel® III

The AstroCel III filter provides high-grade protection at airspeeds up to 600 FPM and is designed to help reduce energy use and operating costs. Its longer service life and superior strength make it ideal for demanding operating conditions in critical applications.

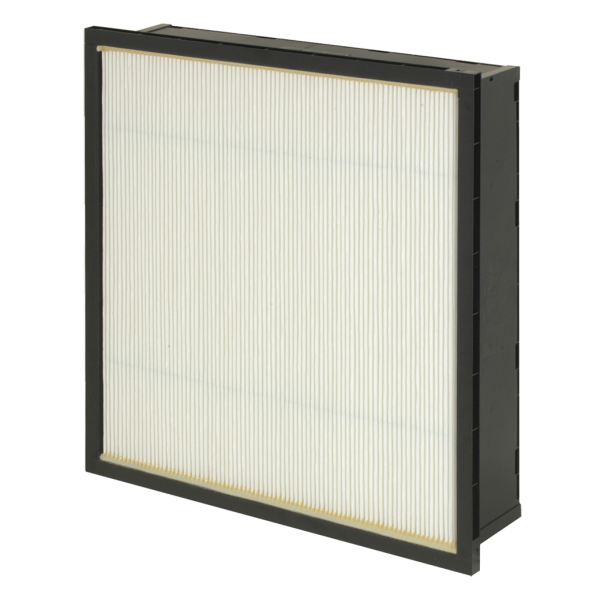

BioCel® I

The BioCel I provides near-HEPA level filtration of fine airborne contaminants for critical applications where very clean air is required. Choose it for pharmaceutical plants, hospitals and food and beverage production sites. The BioCel I can replace less efficient box-style filters without needing special frames or latches.

VariCel® M-Pak

The VariCel M-Pak filter offers the same media area as traditional 12" deep box filters in a 6" deep design. The result is comparable efficiency and performance in half the footprint. Sturdy cell sides and dual-density media add to the durability and dust-holding capacity, so the filter lasts longer

Wind Turbine Air Filtration

Wind power turbines in offshore and coastal locations are often exposed to very harsh conditions. The air filtration challenge in these applications arrives when the prevailing wind picks up sea spray laden with salt and moisture. Salt corrosion and water ingress can pose a major threat to wind turbine operational efficiency and must be avoided.

HydroPak Filtration

Specifically designed to significantly reduce compressor fouling and the number of water washes required for your gas turbine. The HydroPak is suitable for all ASC filter housings and offers an outstanding combination of filtration efficiency, low cost of operation, and filter life. The EPA E11 filtration grade protects against corrosion, increases gas turbine availability, and lowers operating expenditure

REDClean® Cartridges

AAF’s Nanofibre Flame Retardant (NFR) cartridge is a high-performance filter with a nanofibre outer layer to efficiently collect the smallest particles. Its flame retardant finish will also increase safety, slowing down combustion and flame propagation when handling dust with incandescent particles